Problem:

Concrete tank roof deck deterioration

In the summer of 2016, C-TEC AG, York, NE (800-345-2832), was contacted by a grain company to replace the roof decks on four concrete tanks.

The four tanks were part of a 70-year-old eight-pack slipform annex. The tanks’ concrete roof decks had dipped in the middle by approximately 3/4 inch, enough to hold water and potentially cause a leak or roof collapse.

Solution:

Roof deck replacement, reinforcement, and waterproofing

According to C-TEC Sales Rep Mike Batterton, “the first step in the process was to remove the old roof decks with jackhammers. Once removed, we discovered numerous support beams out of their respective pockets, the root of the problem.” With support beams out of place, the roof deck had begun to sag.

Old, out-of-place beams were replaced. Some steel from old beams was reused as additional support for existing beams. “We decided to reuse some old steel as a way to save money for the facility,” says Batterton.

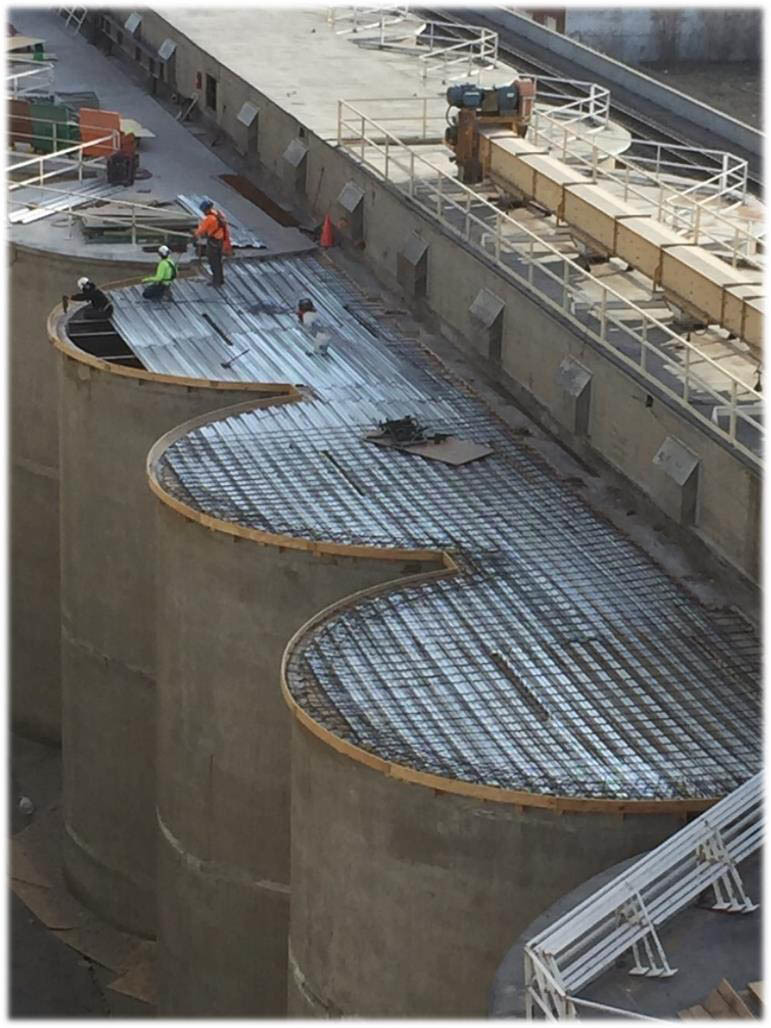

Next, metal sheeting was placed over the support beams, followed by a 60-grade rebar pattern on 1-foot centers. This served as a foundation for a new roof deck.

Concrete then was poured and finished when dry. To finish, Batterton says C-TEC used rollers to apply acryllic primer, two coats of blocker base, two coats of liquid rubber, and lift coating to waterproof the surface and prevent further deterioration of the roof deck.

The three-month project was completed in the fall of 2016.

Reprinted from Grain Journal May/June 2017 Issue

New support beams. Replaced some older, out-of-place beams, with some old beam material used to support the new beams.

Metal sheeting and 60-grade rebar was installed as the foundation for a new concrete roof deck.

New roof deck was treated to resist water and further deterioration. Photos courtesy of C-TEC AG.